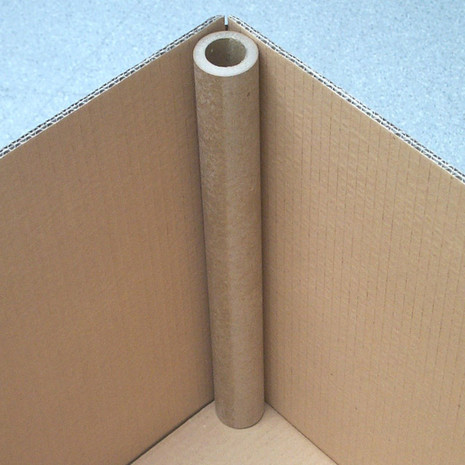

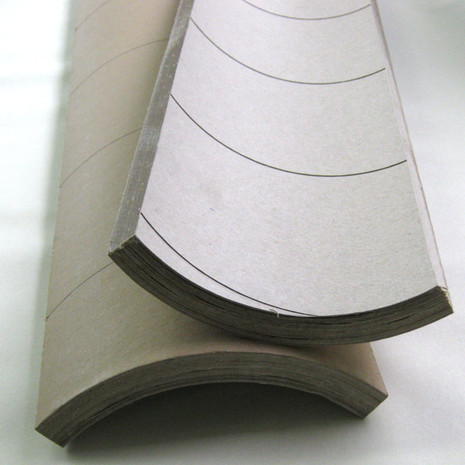

With our cores, we at Paul & Co cover many standardised requirements. In addition you can, of course, rely on us when dealing with customised solutions for special applications. Together with you we develop precisely fitting products corresponding to your requirements.

Your benefits:

- Selected raw material basis

- Narrowest tolerances

- Variable surfaces

- Hygiene standards are met

- Trouble-free operation of automatic packing machines